Products

- Acid Frac Hose (4)

- Oilfield Drilling Hose (34)

- Connector (17)

- Wrapped Cover Wire Spiral Hydraulic Hose (23)

- Smooth Cover Wire Braided Hydraulic Hose (33)

- Wrapped Cover Wire Braided Hydraulic Hose (31)

- Industrial Hose (49)

- Fiber Braided Hose (30)

- Hose Assembly (2)

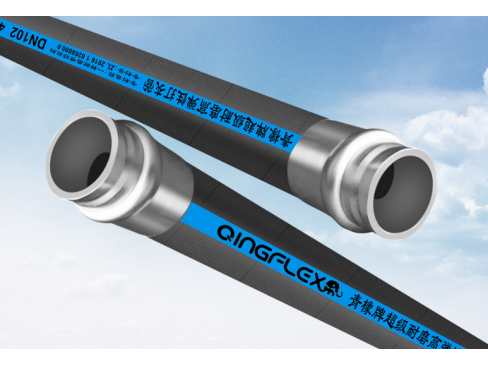

- Concrete Pumping Hose (2)

- Hydraulic Fitting (224)

- Hydraulic Adapter (283)

News

Concrete Pumping Hose: Essential Equipment By Quingflex

A concrete pumping hose is a critical component in the construction and concrete placement industry. Designed to withstand the high-pressure demands of pumping concrete from mixers to the desired location, these hoses play a vital role in ensuring precise, efficient, and safe concrete delivery on job sites. Whether you're working on residential foundations, commercial buildings, or large-scale infrastructure projects, the right concrete pumping hose can make all the difference in performance and productivity.

What Is a Concrete Pumping Hose?

What Is a Concrete Pumping Hose?

A concrete pumping hose is a heavy-duty, flexible hose specifically engineered to handle the highly abrasive and viscous nature of wet concrete. Typically constructed with a combination of strong rubber and reinforced layers such as synthetic fabrics or steel wire, these hoses are capable of withstanding high internal pressures and tough working conditions.Concrete pumping hoses come in various diameters—most commonly 2", 2.5", 3", 4", or 5"—and are available in different lengths to suit the scale and layout of different construction sites. They can be attached to boom pumps, line pumps, or trailer pumps depending on the job.

Key Features and Benefits of Concrete Pumping Hose

1.Durability and Abrasion ResistanceConcrete is an extremely abrasive material, and these hoses are built to resist wear, tear, and cracking. A high-quality pumping hose will last longer even under continuous heavy use.

2.High Pressure Tolerance

Concrete hoses must handle high pumping pressures, often exceeding 800 psi. Reinforced designs ensure the hose maintains integrity under these intense conditions.

3.Flexibility and Maneuverability

Despite their strength, concrete hoses are flexible enough to navigate complex site layouts, tight spaces, or high elevations—making concrete placement faster and more efficient.

4.Safety Enhancements

Many concrete pumping hoses feature safety cuffs or steel end fittings to minimize blowouts or disconnections. Regular maintenance and proper coupling ensure safer operations.

5.Compatibility

These hoses are compatible with various types of concrete pumps and can be easily coupled with reducers, clamps, and other attachments.

Applications of Concrete Pumping Hoses

●Residential Construction: Driveways, foundations, slabs, and patios●Commercial Projects: High-rise buildings, parking structures, and industrial flooring

●Infrastructure: Bridges, tunnels, dams, and roadways

●Shotcrete: Sprayed concrete for retaining walls or mining applications

Tips for Proper Use and Maintenance of Concrete Pumping Hose

●Inspect Regularly: Check for visible signs of wear, cuts, or leaks before each use.●Proper Storage: Store hoses in a dry, shaded area to avoid UV damage or moisture buildup.

●Clean After Use: Flushing the hose with water or a cleaning ball prevents blockages and extends hose life.

●Use Safety Gear: Always wear protective equipment and follow industry safety standards during operation.

A concrete pumping hose is more than just a piece of equipment—it's a lifeline that connects your concrete pump to precise, on-site placement. Choosing the right hose ensures smooth operation, minimizes downtime, and increases the overall quality of your construction work. Whether you need a durable hose for a small residential job or a heavy-duty option for commercial and industrial applications, investing in a reliable concrete pumping hose is a smart and necessary choice.